How Do Solid Wires Flat Wires And Stranded Wires Differ

- By: Electric Wire Manufacturers

- 2022-10-20

Among the many metal wires available on the market, stranded copper wires are, without a doubt, the most popular. There is no other metal that has as many qualities that lend themselves to the production of electrical cables as copper does. In addition to its moderate conductivity, copper is recognized for its ability to transmit low-voltage energy with ease. As the top Multi Strand Wire Manufacturers, let us mention some different uses of both types:

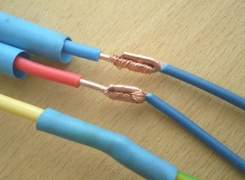

Stranded Wire:

A wide range of applications can be achieved using stranded wire.

Because of the bundling of the wires, stranded wires are more flexible, complex, and delicate than conventional wires. It is more suitable for indoor use on circuit boards, speaker cables, electronic gadgets, and other places where the electrical components of the circuit must be bent and twisted to get them connected in order for the circuit to function. There is no better place to use stranded wire than on a door of an automobile, for example, which will be bent a lot when it is being used.

Stranded wire has a number of advantages.

- In comparison with solid wire, the braids wrapped around stranded cables have a few distinct advantages.

- It is flexible

- There will be no division or severance of it

Applications of Stranded Wire:

There is a wide range of uses for stranded wires in interior applications that require bends and twists to connect electrical components, including:

The circuit board, which is the heart of a circuit, requires stranded wires.

These wires are used in speakers.

Assembly of electromechanical components requires these wires.

Flat Wire

An example of flat wire applications would be:

A flat wire becomes very flexible when it is bent in the plane of its narrow cross-section when it is bent in a certain way. There have been many applications where this pliability is used. It can be utilized in items such as drawers, doors, rotating arms, and the list goes on and on, where a continuous or high level of flexing is required. The fact that all conductors and insulation share tensile loads evenly improves strength.

According to your needs, you can scroll through the website of the leading Parallel Flat Wire Manufacturers. We offer top-quality products at affordable prices.

The reliability of flat cables is one of the top reasons for using them.

By using a flat cable, you are often able to remove a great deal of the weight associated with traditional wires. A flat wire is remarkably flexible.

The efficiency of space can be improved:

- By removing superfluous insulation, fillers, and tapes from flat cables, the size and physical volume of the cable are reduced.

- The low profile of this item also allows it to hug surfaces and take advantage of tight or otherwise empty spaces.

- It is possible to stack or layer flat cables with nearly no dead space between the cables because flat cables have a rectangular cross-section, resulting in the highest conductor density for a given volume as a result.

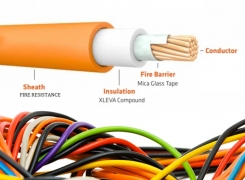

The solid wire:

The advantage of solid wire is that it is heavier, designed to withstand all weather conditions, anticorrosive, tough, and can be used in frequent but minor movements. In order to carry electricity through a building structure, solid wire is a good choice since it requires a high current, minimal movement, and long-lasting tensile strength and durability.

There are several advantages associated with solid wires.

- A weather-resistant finish

- Featured anticorrosive properties

- Applications for Solid Wire at a Low Cost

- In general, solid wires are more suitable for outdoor or heavy-duty applications that require larger currents as well as more rigorous durability.

- Used in infrastructure development

- Used in the controls of a vehicle

- Suitable for outdoor use