Everything You Need to Know About Commercial Wire and Cable

- By: Electric Wire Manufacturers

- 2023-03-17

Commercial wire and cable are the backbone of any electrical system, providing power and connectivity throughout buildings and industries. These wires and cables come in various types and sizes, depending on the application and environment they will be used in. Aluminium wire cable, on the other hand, is a relatively new addition to the market, offering a lightweight and cost-effective alternative to traditional copper wires.

Understanding Commercial Wire and Cable

Commercial wire and cable are designed to meet the needs of various industries, including construction, manufacturing, and telecommunications. Commercial Wire and Cable Manufacturers in Delhi engineer it to be durable, reliable, and able to withstand harsh environmental conditions. They can be made from different materials, such as copper, aluminium, or even fibre optic, depending on the specific application requirements.

Benefits of Commercial Wire and Cable

Commercial wire and cable are highly durable and can last for several years without requiring replacement. They are also resistant to heat, moisture, and other environmental factors, making them ideal for use in harsh conditions. Additionally, commercial wires and cables can be customised to meet specific application requirements, ensuring optimal performance and reliability.

Different Types of Commercial Wire and Cable

There are several types of commercial wire and cable available in the market, including copper wire, aluminium wire, coaxial cable, fibre optic cable, and many others. Each type has its unique properties and is suited for specific applications. For example, coaxial cable is commonly used in telecommunications and broadcasting industries, while fibre optic cable is ideal for high-speed data transfer.

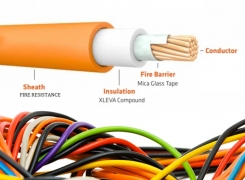

Commercial Wire and Cable Manufacturing Process

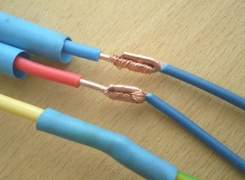

The manufacturing process of commercial wire and cable involves several steps, including wire drawing, annealing, stranding, insulation, and jacketing. The wire drawing process involves pulling a metal rod through a series of dies to reduce its diameter, while annealing involves heating the wire to a specific temperature to improve its ductility. Stranding involves twisting several wires together to form a single cable, while insulation and jacketing involve adding a protective coating to the cable to prevent damage and ensure longevity.

Understanding Aluminium Wire Cable

Aluminium wire cable is a lightweight and cost-effective alternative to traditional copper wires. It is commonly used in residential and commercial applications and is an excellent choice for long-distance power transmission due to its low resistance. Additionally, aluminium wire cable is highly resistant to corrosion and can withstand harsh environmental conditions.

Benefits of Aluminium Wire Cable

One of the primary benefits of aluminium wire cable is its low cost compared to copper wire. It is also much lighter in weight, making it easier to handle and install. Additionally, aluminium wire cable has a lower resistance than copper wire, making it ideal for long-distance power transmission.

Different Types of Aluminium Wire Cable

There are several types of aluminium wire cable available in the market, including single-conductor, multi-conductor, and aluminium-clad steel wire. Each type has its unique properties and is suited for specific applications. For example, single-conductor aluminium wire cable is commonly used for overhead power transmission lines, while multi-conductor aluminium wire cable is ideal for use in motors, generators, and transformers.

Aluminium Wire Cable Manufacturing Process

The manufacturing process of aluminium wire cable involves several steps, including wire drawing, stranding, insulation, and jacketing. Aluminium Wire Cable Manufacturers in India use the wire drawing process which involves pulling an aluminium rod through a series of dies to reduce its diameter, while stranding involves twisting several wires together to form a single cable. Insulation and jacketing involve adding a protective coating to the cable to prevent damage and ensure longevity.

Conclusion

Commercial wire and cable are an essential part of any modern building's infrastructure. Aluminium wire cable is becoming increasingly popular because it is cheaper than copper wire cable and is lighter in weight.

However, there are some disadvantages to using aluminium wire cable, including higher resistance, oxidation, and corrosion. If you are looking for high-quality commercial cable or aluminium wire, it is essential to work with a reputable manufacturer like Electric Wires & Cables Delhi as they have experience in the industry and uses high-quality materials in their products.